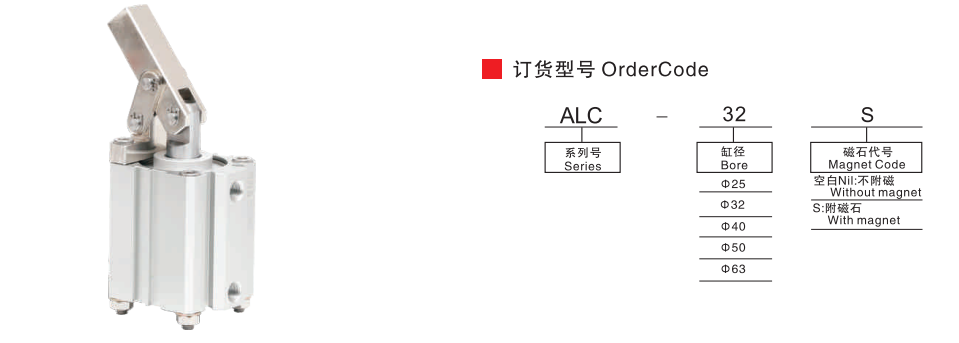

ALC Series aluminum acting Lever irin pneumatic misali iska kwampreso Silinda

Takaitaccen Bayani

ALC jerin aluminum lever pneumatic misali iska Silinda ne ingantaccen kuma abin dogara pneumatic actuator amfani da ko'ina a fagen masana'antu aiki da kai. Wannan jerin silinda na matsawa iska an yi su ne da kayan haɗin gwiwar aluminum masu inganci, waɗanda suke da nauyi kuma masu ɗorewa. Ƙirar da aka yi amfani da shi yana sa aiki ya fi dacewa da sassauƙa, dacewa da kayan aiki daban-daban na iska da tsarin inji.

The ALC jerin iska matsawa Silinda rungumi dabi'ar misali Silinda tsarin, wanda yana da kyau kwarai sealing yi da kuma barga aiki halaye. Silinda tana ɗaukar ƙira mai yin aiki sau biyu, wanda zai iya cimma aikin ƙwanƙwasa bidirectional kuma ya ba da ƙarfi mai ƙarfi da tashin hankali. Bangaren ciki na silinda yana ɗaukar ingantacciyar fasahar injuna don tabbatar da hatimi tsakanin fistan da jikin Silinda, rage asarar gogayya, da tsawaita rayuwar sabis.

Za a iya zaɓar silinda na iska na ALC tare da diamita daban-daban da tsayin bugun jini bisa ga buƙatun aikace-aikacen daban-daban, biyan buƙatun yanayin yanayin aiki daban-daban. Shigar da shi yana da sassauƙa kuma ana iya amfani da shi tare da nau'ikan bawul ɗin pneumatic da masu kunnawa don cimma iko ta atomatik. Wannan jerin nau'ikan silinda na matsawa iska yana da sauƙin aiki, mai sauƙin kulawa, kuma yana da ingantaccen aminci da karko.

Cikakken Bayani

Ƙayyadaddun Fasaha

| Girman Bore (mm) | φ25 | φ32 | φ40 | φ50 | φ63 |

| Diamita Piston Rod (mm) | φ10 | φ12 | φ16 | φ20 | φ20 |

| Jimlar bugun jini (mm) | 20 | 23 | 25 | 30 | 35 |

| Wurin Matsi (cm²) | 4.91 | 8.04 | 12.57 | 19.63 | 31.17 |

| Theoretical Holding Force (6kg/cm²) | 15 | 25 | 44 | 71 | 136 |

| Ruwa | Jirgin da aka matsa | ||||

| Max.Matsin Aiki | 10kg/cm² | ||||

| Tsawon Matsalolin Aiki | 1-7kg/cm² | ||||

| Yanayin Aiki | Aiki sau biyu | ||||

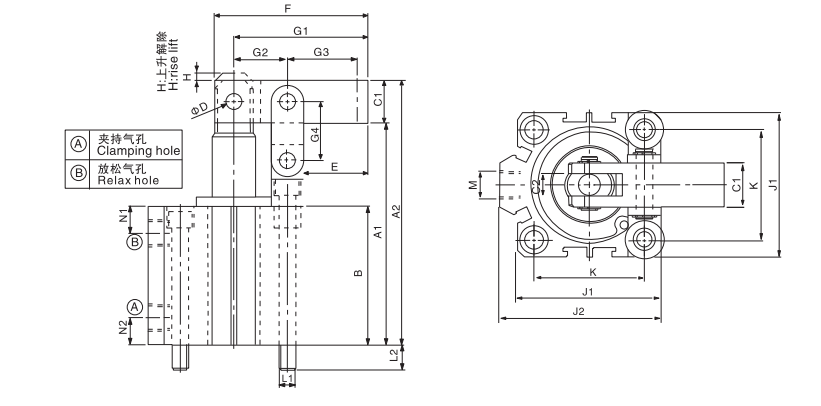

Girma

| Girman Bore (mm) | C1 | C2 | D | E | F | G1 | G2 | G3 | G4 | H | J1 | J2 | K | L1 | L2 | M | N1 | N2 |

| φ25 | □ 12.7 | 6 | φ5 | 25 | 50 | 45 | 14 | 27.5 | 17 | 3 | 40 | 42 | 28 | M5x0.8 | 11.5 | M5x0.8 | 9 | 5.5 |

| φ32 | □ 15.9 | 8 | φ6 | 31 | 60 | 54 | 17 | 33 | 20 | 3 | 44 | 50 | 34 | M5x0.8 | 11.5 | G 1/8 | 9 | 9 |

| φ40 | □ 15.9 | 8 | φ6 | 32 | 65 | 58 | 20 | 34 | 22 | 3 | 52 | 58.5 | 40 | M6x1.0 | 11.5 | G1/8 | 9.5 | 7.5 |

| φ50 | □19 | 10 | φ8 | 35 | 75 | 66 | 23 | 38 | 27 | 3 | 62 | 71.5 | 48 | M6x1.0 | 12.5 | G1/4 | 10.5 | 10.5 |

| φ63 | □ 22.2 | 10 | φ8 | 38.5 | 85 | 76 | 29.5 | 40.5 | 32 | 3 | 75 | 84.5 | 60 | M6x1.0 | 12.5 | G1/4 |